What Is an In-Line Warehouse Layout?

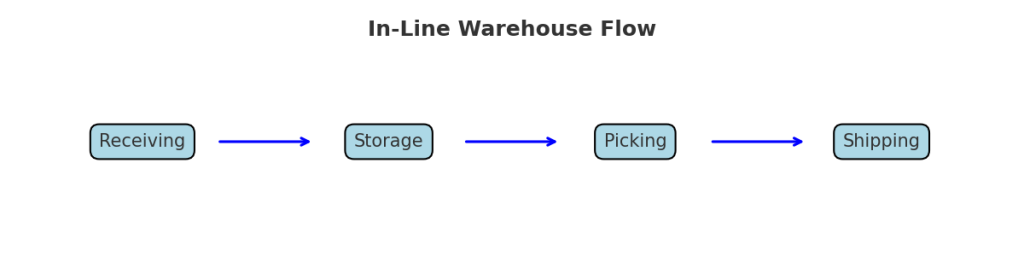

An in-line warehouse flow, also known as a straight-through flow, is a layout configuration where inbound and outbound

areas are positioned on opposite sides of the warehouse. Goods move in a linear direction from receiving to

shipping without backtracking.

This flow is designed for high-volume operations that require clear separation between inbound and outbound activities.

How the In-Line Flow Works

In an in-line layout:

- Goods enter the warehouse through inbound docks

- Items move progressively through storage or picking areas

- Order preparation occurs along the flow path

- Completed orders exit through outbound docks on the opposite side

The movement follows a straight, forward direction, reducing cross-traffic.

Advantages of an In-Line Warehouse Flow

Key advantages include:

- clear separation of inbound and outbound traffic

- reduced congestion near docks

- high throughput capability

- efficient handling of large volumes

- easier scaling for growth

- improved safety and visibility

This flow is common in distribution centers and large warehouses.

Limitations and Constraints

Despite its strengths, the in-line flow has limitations:

- longer travel distances compared to compact layouts

- higher space requirements

- less flexibility in small buildings

- increased walking for picking operations

It is not always suitable for constrained or low-volume environments.

In-Line Flow vs U-Shaped Flow

- In-Line Flow – linear, scalable, high throughput

- U-Shaped Flow – compact, flexible, short travel distances

The optimal choice depends on volume, space, and operational complexity.

When to Use an In-Line Flow

An in-line warehouse flow is recommended when:

- inbound and outbound volumes are high

- product range is large

- building length supports linear movement

- operations require strong separation of activities

- future growth is expected

It is less effective in small or space-constrained warehouses.

Example of In-Line Material Flow

- Goods are received at one end of the warehouse.

- Items move through inspection and storage zones.

- Orders are picked and moved toward the opposite side.

- Packed goods are shipped directly from the outbound dock.

This design forms a straight material flow — ideal for manufacturing facilities or warehouses with

separated inbound/outbound docks.

Comparison With U-Shaped Layout

| Aspect | In-Line Layout | U-Shaped Layout |

|---|---|---|

| Flow Direction | Straight | Circular (U pattern) |

| Dock Configuration | Separate inbound/outbound | Shared inbound/outbound |

| Space Requirement | Higher | Compact |

| Travel Distance | Longer | Shorter |

| Best For | Linear buildings | High-throughput warehouses |

FAQ – In-Line Warehouse Flow

Why is the in-line flow used in large warehouses?

Because it supports high volumes and clear separation of activities.

Does in-line flow reduce congestion?

Yes, especially around docks and main traffic areas.

Is in-line flow suitable for e-commerce?

Yes, particularly for high-volume fulfillment centers.

Can in-line flow be combined with zoning?

Yes. ABC zoning is often applied along the flow path.

Is automation required for in-line flow?

No, but it is often easier to automate compared to compact layouts.