What Is the Inbound Process in Warehouse Operations?

The inbound process covers all activities related to receiving goods into the warehouse, from arrival at the dock to initial

verification and preparation for storage. It ensures that incoming products are correctly identified, checked, and

recorded before entering stock.

A stable inbound process is the foundation of accurate inventory and reliable downstream operations.

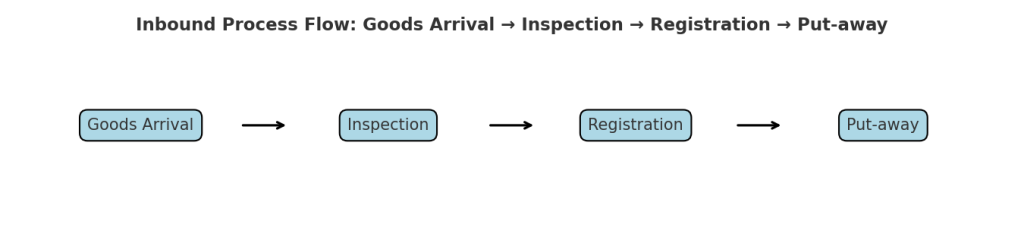

Standard Inbound Process – Step by Step

A typical inbound process includes:

- Arrival and Dock Assignment

Inbound shipments arrive and are assigned to receiving docks. - Unloading

Goods are unloaded and staged in the receiving area. - Identification and Documentation

Products are identified using product codes, labels, or reference documents. - Quantity and Quality Check

Received quantities and basic quality are verified. - Exception Handling

Discrepancies, damages, or missing items are recorded. - System Registration

Inventory records are updated to reflect received quantities. - Preparation for Put-Away

Goods are prepared for movement to storage or picking locations.

Clear definition of each step prevents errors and delays.

What is the most common inbound mistake?

Skipping verification to save time, which creates bigger issues later.

Example of Receiving and Put-Away

Imagine a supplier delivers 100 pallets of Product A:

- At the dock, the goods are checked against the purchase order.

- 2 pallets are rejected due to damage.

- 98 pallets are registered and assigned to racks R01–R05.

- Staff use forklifts to put away pallets into designated slots.

This ensures accurate inventory levels and product traceability.

Inbound vs Put-Away

Although closely linked, inbound and put-away are distinct processes:

- Inbound focuses on receiving, checking, and registering goods

- Put-away focuses on moving goods to storage or picking locations

Separating these processes improves control and reduces congestion.

Inbound, Layout, and Data Accuracy

Inbound efficiency depends on:

- sufficient dock space and staging areas

- clear separation between inbound and picking zones

- structured location coding

- clean product and supplier master data

- accurate documentation

Poor layout or data issues at inbound propagate errors across all warehouse operations.

Operational Best Practices for Inbound

To improve inbound performance:

- define dedicated receiving and inspection areas

- avoid mixing inbound with returns or picking

- standardize checking procedures

- register discrepancies immediately

- label goods clearly before put-away

- coordinate inbound schedules with staffing

- keep inbound flow simple and visible

Inbound stability reduces downstream rework.

FAQ – Inbound Process in Warehouse Operations

Why is inbound so critical for warehouse accuracy?

Because all inventory data starts at receiving.

Should inbound and put-away be handled by the same team?

They can be, but the processes should remain distinct.

How do inbound errors affect picking?

They cause stock discrepancies, delays, and picking errors.

Can small warehouses formalize inbound without a WMS?

Yes. Simple procedures and accurate data are sufficient.

Related Tools and Pages

Inbound operations rely on accurate data and clear processes. Explore:

- Warehouse Organization Principles

- Warehouse Layout and Operational Flow

- U-Shaped Warehouse Flow

- In-Line Warehouse Flow

- Replenishment Process

- Picking Process in Warehouse Operations

- Returns Process

- Master Data for Warehouse

- Stock Movement Template

- Warehouse Manager User Guide

These resources help integrate inbound into the overall warehouse system.