The 5S methodology is one of the simplest and most effective tools for improving warehouse organization,

compliance, and day-to-day efficiency. Originally developed in Japan as part of lean manufacturing, 5S helps

teams maintain a clean, structured, and predictable work environment. In warehouses, 5S supports safer operations,

reduces search time, increases picking accuracy, and creates a professional culture of discipline.

Warehouse managers often ask how to apply 5S in a practical way or whether 5S brings real value in small warehouses.

The truth is that 5S is not about perfection or expensive tools — it is about simple, visible improvements that help workers

perform their tasks more consistently. When implemented correctly, 5S becomes the foundation for all other improvement

projects: slotting, replenishment, safety audits, and even WMS digitalisation.

Table of Contents

- Explanation of Each “S”

- Why 5S Matters in Logistics Operations

- How to Implement 5S in a Warehouse

- Training Exercise: Understanding the Need for 5S

- Downloadable 5S Audit Checklist for Warehouse Managers

- Conclusion and Recommendations

Explanation of Each “S”

1. Sort (Seiri)

Remove unnecessary items from the work area and keep only what is truly needed.

In a warehouse, this includes outdated labels, broken tools, old packaging, and obsolete inventory.

A common question is how often sorting should be done — best practice is monthly or after major season changes.

2. Set in Order (Seiton)

Everything must have a defined place. Aisles, tools, pallets, and documents must be positioned for fast access.

This step improves walking flow and helps new employees learn the warehouse layout faster.

3. Shine (Seiso)

Clean the area and identify sources of dirt or waste.

In warehouses, Shine is not only about cleaning floors — it also includes checking racks, scanning devices, pallet quality, and label condition.

4. Standardize (Seiketsu)

Define rules, visual cues, and routines so the first three S’s become part of daily practice.

Examples include color coding, aisle marking, inspection forms, and standard operating procedures.

5. Sustain (Shitsuke)

The most difficult step — maintaining discipline over time.

Sustain is achieved through short inspections, team responsibility, and continuous improvement.

Why 5S Matters in Logistics Operations

In logistics, time, space, and precision are critical. Warehouses are dynamic environments where delays,

misplaced items, or inefficient workflows can directly impact service quality and profitability.

The 5S methodology offers a structured way to reduce these inefficiencies by creating order,

eliminating waste, and maintaining standards.

Here’s why 5S is particularly valuable in logistics operations:

- Improved Picking Accuracy: Clearly labeled and organized storage areas help reduce picking errors.

- Reduced Search Time: Workers spend less time looking for tools, materials, or paperwork.

- Faster Turnaround: Streamlined layouts and processes allow for faster receiving, dispatching, and inventory control.

- Higher Safety Standards: Clean, obstacle-free zones reduce the risk of accidents.

- Consistent Results: Standardized procedures ensure that tasks are performed the same way every time.

- Team Engagement: 5S empowers teams to take ownership of their workspace and continuously improve it.

While 5S is often associated with manufacturing, its principles are perfectly suited to warehouses, where structure and

visibility translate directly into better performance. Logistics professionals who adopt 5S benefit from a more disciplined,

efficient, and safe work environment.

How to Implement 5S in a Warehouse

Implementing 5S in a warehouse is a structured process that requires team involvement, management support,

and ongoing discipline. While the methodology is simple in theory, its real power lies in consistent application.

Below are the five steps of 5S, adapted specifically for warehouse environments:

1. Sort (Seiri) – Remove what you don’t need

Identify and eliminate items that are not required for daily operations. This includes obsolete stock, broken tools,

outdated documents, or unused materials. Use red tags to mark items that need to be removed or relocated.

Warehouse example: Clear expired inventory or damaged packaging from active picking areas.

2. Set in Order (Seiton) – Arrange everything for easy access

Organize all necessary items so they are easy to find, reach, and return. Use visual cues like labels, floor markings,

shadow boards, or colored bins.

Warehouse example: Designate fixed locations for tools, scanners, pallets, and packing supplies with clear labeling.

3. Shine (Seiso) – Clean and inspect

Go beyond basic cleaning. Inspect and clean equipment, shelving, and work areas regularly to detect early signs

of damage or inefficiency.

Warehouse example: Establish daily cleaning schedules for aisles, pallet racking, and high-traffic zones.

4. Standardize (Seiketsu) – Make best practices consistent

Develop checklists, visual standards, and clear instructions that all employees follow. Consistency

helps avoid confusion and supports training for new staff.

Warehouse example: Create standard layouts for picking zones and inbound/outbound areas.

5. Sustain (Shitsuke) – Keep it going

Build habits through regular audits, feedback, and recognition. Make 5S part of the warehouse culture with

leader support and visible results.

Warehouse example: Assign a 5S champion or team to review areas weekly using an audit checklist.

When done correctly, 5S becomes more than a workplace organization tool—it becomes a mindset for

operational excellence.

Training Exercise: Understanding the Need for 5S

To help warehouse teams experience the difference that 5S can make, this simple but powerful training exercise

can be conducted in just a few minutes. It demonstrates how disorganization impacts performance and

how visual clarity improves speed and accuracy.

Objective:

To show how workplace organization influences task execution time and error rates.

How the Exercise Works:

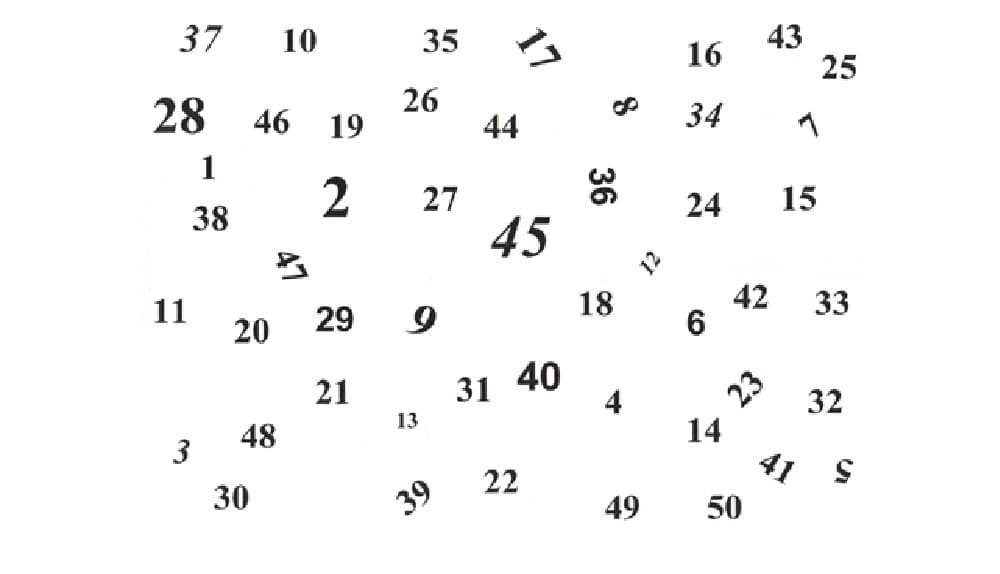

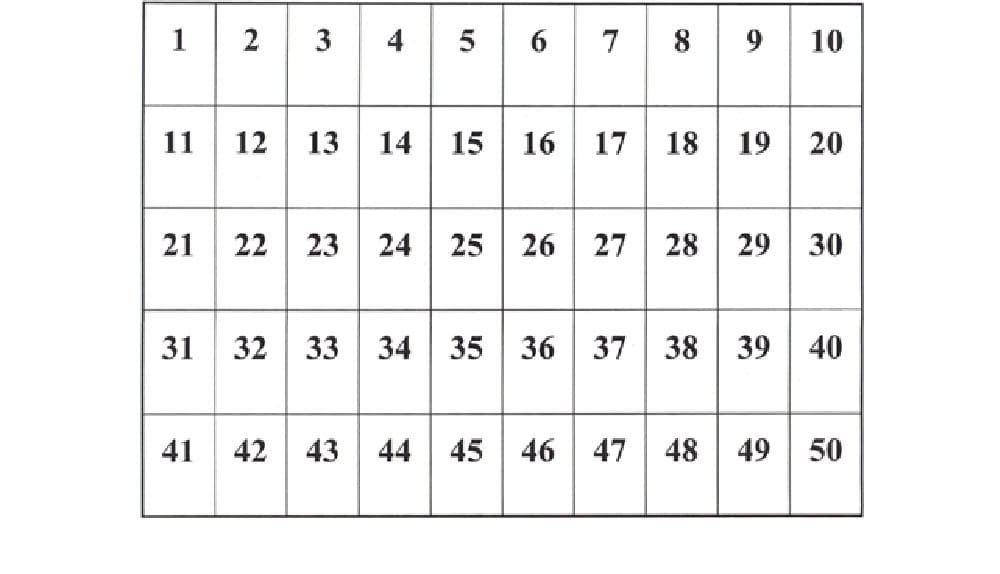

- Step 1 – Find the Numbers

Present participants with a cluttered worksheet where numbers 1 to 50 are scattered randomly.

➤ Goal: Find and mark numbers in ascending order within 40 seconds. - Steps 2 to 4 – Repeat with Improved Visual Organization

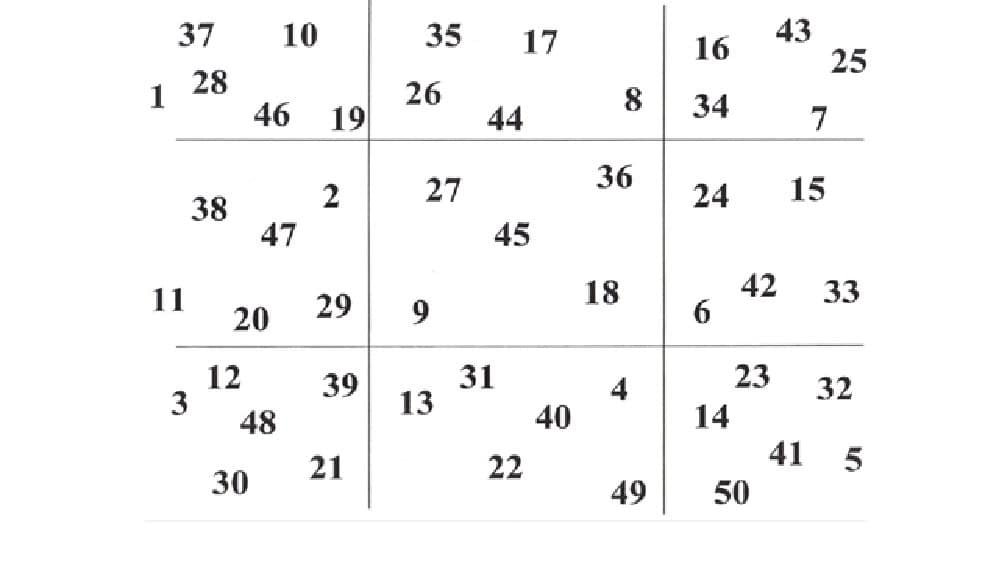

In each step, the same task is repeated, but the visual layout improves:

- Step 2: Slightly structured format

- Step 3: More aligned rows/columns

- Step 4: Clearly ordered zones or groups ➤ Participants usually complete the task

faster and with fewer mistakes as order increases.

Lesson Learned:

This exercise helps participants:

- Feel the impact of disorder

- Understand the value of sorting and setting in order

- Appreciate the role of standardization and visual clarity

It’s a great warm-up or onboarding tool for warehouse staff before a real 5S rollout.

This exercise illustrates how visual organization improves performance. Each slide shows a

progressive improvement in structure and clarity.

Downloadable 5S Audit Checklist for Warehouse Managers

Simple 5S Audit Template (Excel)

We offer a clean and easy-to-use 5S scoring audit sheet, built specifically for small logistics operations.

This tool allows managers to periodically evaluate workplace organization using the 5S principles.

You can download “5s audit checklist” and open this file using Microsoft Excel .

Conclusion and Recommendations

Implementing 5S in warehouse management is more than just organizing shelves or labeling tools —

it’s about creating a culture of discipline, safety, and continuous improvement.

When applied consistently, 5S drives measurable gains in efficiency, quality, and employee engagement.

For small and medium-sized logistics operations, even basic 5S efforts can produce quick wins.

The key is to start small, involve your team, and build habits over time.

Warehouse supervisors often ask

How frequently 5S audits should be performed ?

Most SMEs run audits every two weeks or once per month, depending on seasonality.

Another common question is whether 5S is still needed when a WMS is implemented.

The answer is yes — 5S ensures that the physical environment supports the digital system.

A clean, structured warehouse reduces scanning errors and improves productivity.

Managers also ask whether 5S should be documented or applied informally.

Documentation is recommended. Even simple checklists and visual boards help sustain the routine.

Final tips for successful implementation:

- Begin with a pilot area (receiving zone, packing table, etc.)

- Use the visual exercise to introduce the concept to your team

- Audit regularly, using our free Excel-based 5S score sheet

- Recognize and reward team efforts that align with 5S principles

- Document improvements with before-and-after photos

How 5S Supports Warehouse Digitalisation

A warehouse that consistently applies 5S is far easier to digitalise because:

- scanning areas are clean and clearly marked

- operators follow predictable routines

- locations are labelled correctly

- tools and devices are easy to reach

- errors are reduced before WMS implementation

For SMEs planning to introduce scanning or a WMS in the near future, 5S should be the first step.

Whether you’re a warehouse manager, logistics consultant, or process improvement enthusiast —

5S offers a structured path to a cleaner, safer, and more productive warehouse.