Implementing a Warehouse Management System (WMS) is one of the most impactful decisions a warehouse can make.

A well-planned WMS improves accuracy, reduces operational waste, increases visibility, and brings structure to every

warehouse process. However, a WMS is not just a software installation — it is an organizational transformation.

Successful implementation depends on preparation, clear roles, accurate master data, disciplined execution, and measurable KPIs.

Many SMEs ask whether a WMS is too complex or too costly for their warehouse. The truth is that the success of a WMS

depends far more on planning than on budget. A warehouse with clear processes, consistent storage logic, accurate product data,

and trained operators will always implement a WMS faster and more effectively. The purpose of this page is to provide a practical,

structured guide to help SMEs prepare, plan, and evaluate a WMS implementation from a strategic and operational perspective.

1. A Practical Blueprint Structure for SMEs

A WMS Blueprint should be simple, visual, and operational — not a theoretical document.

A strong blueprint typically contains:

- Process Mapping (Receiving → Putaway → Picking → Packing → Dispatch)

- Location architecture (aisles, levels, zones, pick faces, reserve)

- Product Attributes Model (dimensions, pick units, replenishment rules)

- Exception Scenarios (damaged goods, stock differences, partial pallets)

- Operator Roles and Access Rights

- Equipment & Device Mapping (scanners, printers, forklifts)

- KPIs & Reporting Needs

- Integration Requirements (ERP, TMS, Labeling, Accounting)

SMEs often ask how detailed a blueprint should be.

Answer: Just detailed enough to ensure consistency — not so complex that nobody reads it.

2. Project Objective

The goal of a WMS implementation is to automate critical warehouse operations and align them with ERP,

transportation, and courier systems.

Key expected benefits:

- Increased efficiency in receiving, storage, and picking

- Error reduction in order preparation

- Real-time visibility of stock and movements

- KPI-based performance monitoring

3. Scope of Implementation

- Warehouse type: Traditional (non-automated)

- Processes covered: Receiving, storage, picking, packing, shipping, returns

- Integrations: ERP system, courier/TMS

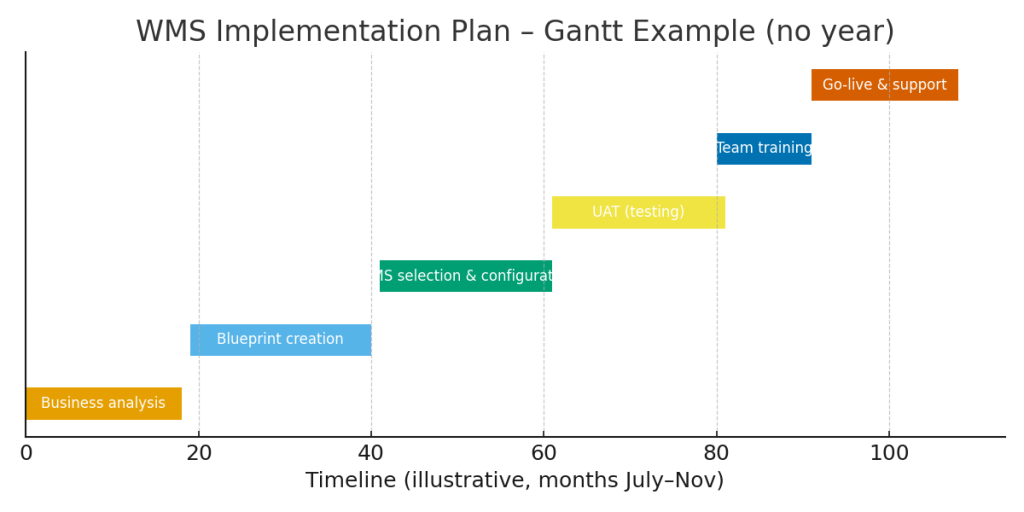

4. Implementation Roadmap (Gantt Chart)

- Business analysis: July 22 – August 9

- Blueprint creation: August 10 – 31

- WMS selection & configuration: September 1 – 20

- UAT (user acceptance testing): September 21 – October 10

- Team training: October 5 – 15

- Go-live & support: October 16 – November 1

5. Roles & Responsibilities (RACI Matrix)

- Project Manager: Accountable for approvals, ensures project delivery

- IT Consultant: Responsible for blueprinting, testing, and support

- WMS Vendor: Configures, trains, and supports system

- Operations: Provides input, validates processes

- Top Management: Oversees and validates key decisions

6. Service Level Agreements (SLA)

| SLA Type | KPI Example | Target |

|---|---|---|

| Delivery time | 98% of orders shipped within 24h | > 98% |

| Picking accuracy | Errors below 0.5% | > 99.5% |

| Receiving time | Completed in max. 4h | 95% < 4h |

| Stock availability | Coverage of active items | > 97% |

| Returns processing | Validated within 48h | > 90% |

7. RAID Register

- Risks: Delays in WMS license delivery, lack of operational team involvement

- Assumptions: Full ERP data access, vendor support available

- Issues: Misalignment between current processes and WMS standard configuration

- Dependencies: IT infrastructure readiness, signed vendor contract

8. Automated WMS Processes

- Receiving with ASN & barcode scanning

- Automatic slotting (location assignment)

- Optimized picking (wave, batch, RF scanning)

- Guided packing & consolidation

- FIFO/Lot/Expiry traceability

- Automated cycle counting

- Courier integration & AWB generation

- Real-time KPI dashboard & SLA alerts

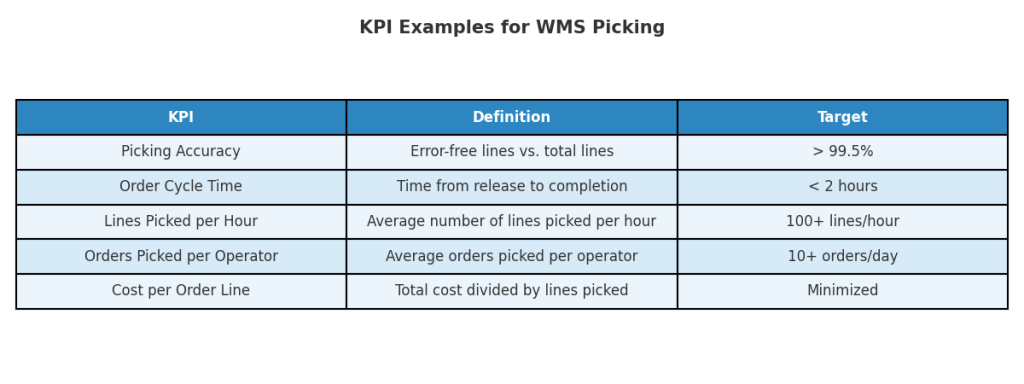

9. KPI Focus for Picking

Efficient order picking is a cornerstone of WMS performance. Common KPIs include:

- Picking accuracy (%): error-free order lines vs. total lines

- Order cycle time: time from order release to completion

- Lines picked per hour (productivity): average output per operator

- Orders picked per operator: workload balance

- Cost per order line picked: efficiency of resources used

These KPIs ensure continuous monitoring and improvement of warehouse operations.

Warehouse managers often ask which KPI matters most ?

Answer: Stock accuracy — everything depends on it.

10. Example:

WMS Implementation in a 12-Operator Warehouse

A mid-sized warehouse implemented a WMS over 10 weeks.

Key actions taken:

- cleaned and standardized location codes

- consolidated product master data

- trained operators using real scenarios

- mapped all exceptions

- created KPI dashboards

- tested receiving, picking, and replenishment flows

Results after 6 months:

- stock accuracy increased from 88% → 98%

- picking productivity improved by 22%

- customer complaints dropped by 40%

The example shows that structured preparation is more important than the software itself.

11. The Most Common Implementation Mistakes

- unclear location architecture

- incorrect or incomplete product master data

- insufficient operator training

- skipping exception scenarios

- no pilot test or isolated testing

- poor communication between teams

- expecting the WMS alone to “fix” process issues

Avoiding these mistakes can reduce implementation time by 20–30%.

Conclusion

A successful WMS implementation plan combines structured project management (Gantt, RACI, RAID),

strict performance targets (SLA), and continuous monitoring through KPIs.

By following this roadmap, companies secure a smooth transition to a digital warehouse environment that

improves accuracy, speed, and scalability.

More about WMS Blueprint Best Practices