What Is the Picking Process in Warehouse Operations?

The picking process is the activity of collecting products from storage locations to fulfill customer orders.

It is one of the most labor-intensive operations in the warehouse, representing up to 50% of total operating costs.

Efficient picking is critical for order accuracy and timely deliveries.

Improving picking efficiency is one of the fastest ways to improve overall warehouse performance.

Types of Picking Methods

Several picking methods are commonly used in warehouses:

- Single Order Picking – one picker collects all items for a single order.

- Batch Picking – one picker collects items for multiple orders at once.

- Zone Picking – pickers work in assigned zones, and orders are consolidated later.

- Wave Picking – combines batch and zone picking, releasing orders in waves for efficiency.

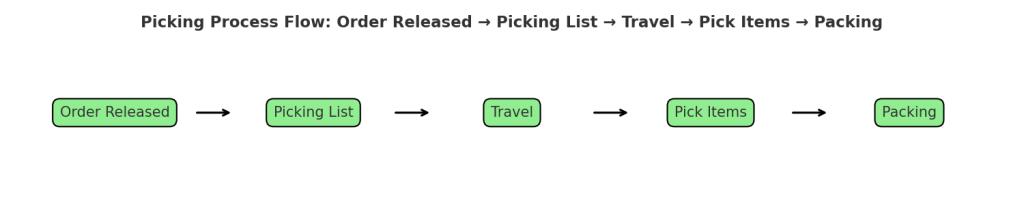

Step-by-Step Example of Order Picking

- The order is released from the system.

- The picker receives a picking list or device instruction.

- The picker travels to each product location.

- Items are picked, scanned, and placed in a container.

- The order is moved to packing or shipping.

Example: For an order of 10 units of Product A and 5 units of Product B, the picker collects items from

two different racks and prepares them for packing.

Challenges in the Picking Process

- Long travel distances within the warehouse.

- Picking errors leading to wrong or missing items.

- Bottlenecks during peak order periods.

- High labor costs due to inefficient routing.

Operational Best Practices for Picking

To improve picking accuracy and speed:

- apply ABC zoning for product placement

- keep picking locations clean and standardized

- avoid emergency replenishment

- minimize exceptions and special cases

- use clear product identification

- review picking errors regularly

- design routes to minimize walking distance

Small improvements in picking create large operational gains.

Standard Picking Process – Step by Step

A typical warehouse picking process follows these steps:

- Order Release

Customer orders are released for picking based on priority or schedule. - Picking List or Task Creation

A picking list or task is generated manually or digitally. - Item Retrieval

Operators retrieve products from defined picking locations. - Quantity Verification

Picked quantities are checked against the order. - Order Consolidation

Picked items are grouped by order, route, or customer. - Transfer to Packing or Dispatch

Orders move to the next operational stage.

Each step must be clearly defined to avoid errors and delays.

Picking, Layout, and Replenishment

Picking performance depends heavily on layout and replenishment:

- fast movers should be placed in accessible picking zones

- picking and replenishment flows must be separated

- poor replenishment causes picking interruptions

- clear location coding reduces search time

Picking efficiency is a system result, not an isolated activity.

FAQ – Picking Process in Warehouse Operations

Why is picking the most critical warehouse process?

Because it consumes most labor time and directly affects customer service.

Which picking method is best?

There is no universal best method. It depends on order volume and layout.

How does replenishment affect picking?

Poor replenishment causes picking delays and stockouts.

Can small warehouses optimize picking without a WMS?

Yes. Clear layout, master data, and simple rules are enough.

How can picking errors be reduced?

Through standardized locations, clean master data, and simple verification steps.

Related Tools and Pages

Picking is supported by accurate data, layout, and processes. Explore: