What Is a U-Shaped Warehouse Flow?

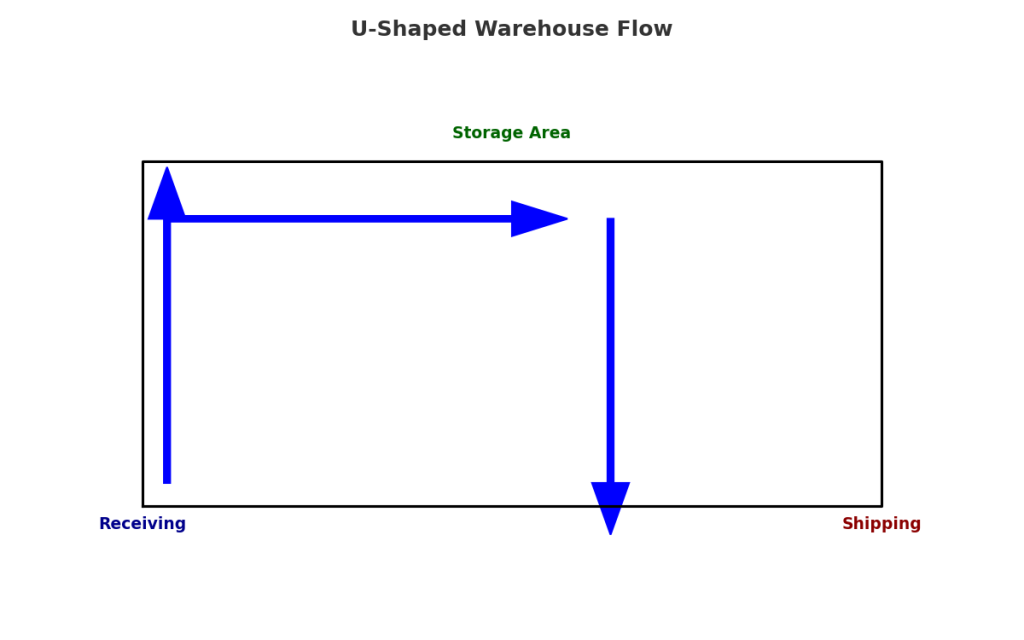

A U-shaped warehouse flow is a layout configuration where receiving and shipping areas are positioned close

to each other, typically on the same side of the building. Goods enter and exit the warehouse through adjacent docks,

creating a U-shaped movement pattern inside the facility.

This flow design is commonly used to reduce travel distances and improve operational control.

How the U-Shaped Flow Works

In a U-shaped layout:

- Goods are received at inbound docks

- Items move into storage or picking areas

- Picking and consolidation occur toward the center

- Orders return toward the outbound docks

- Shipping takes place near the receiving area

The flow forms a “U” shape, minimizing cross-traffic and improving visibility.

Advantages of a U-Shaped Warehouse Flow

Key benefits include:

- reduced travel distance

- shared labor and equipment between receiving and shipping

- better supervision and control

- flexible dock usage

- efficient use of limited space

- simplified material flow

This layout is particularly effective for small and medium warehouses.

Limitations and Constraints

Despite its advantages, a U-shaped flow has limitations:

- congestion risk near docks

- limited scalability for very high volumes

- potential interference between inbound and outbound flows

- requires careful zoning and scheduling

Without clear rules, the benefits can be reduced.

When to Use a U-Shaped Flow

A U-shaped warehouse flow works best when:

- inbound and outbound volumes are balanced

- product variety is moderate

- space is limited

- picking intensity is medium

- operations require close supervision

It is less suitable for very large, high-throughput distribution centers.

U-Shaped Flow vs Other Warehouse Flows

- U-Shaped Flow – compact, flexible, short travel distances

- Straight-Through Flow – clear separation of inbound and outbound, suitable for large DCs

- L-Shaped Flow – compromise solution for constrained buildings

The choice depends on volume, product mix, and operational strategy.

FAQ – U-Shaped Warehouse Flow

Why is the U-shaped flow so popular?

Because it reduces travel distance and allows shared use of space and resources.

Is a U-shaped flow suitable for e-commerce?

Yes, especially for small to medium operations with moderate order volumes.

Can inbound and outbound share the same docks?

Yes, but scheduling and zoning rules must be clearly defined.

Does a U-shaped flow require automation?

No. It works well with manual operations and simple equipment.

Can the layout be scaled later?

Scaling is possible, but very high volumes may require a different flow design.