The Relationship Between Warehouse Layout and Operational Flow

Warehouse layout defines the physical structure of the building, while operational flow defines how goods and

people move through that structure. The two are inseparable: a good layout supports smooth flow, while a poor

layout creates bottlenecks, congestion, and inefficiencies.

Operational flow should always guide layout decisions, not the other way around.

Common Warehouse Flow Types

Most warehouses follow one of these operational flow patterns:

- U-Shaped Flow – inbound and outbound close together

- Straight-Through Flow – inbound on one side, outbound on the opposite side

- L-Shaped Flow – compromise solution for constrained buildings

Each flow type influences travel distance, congestion, and operational control.

How Layout Decisions Affect Daily Operations

Layout choices directly impact:

- receiving and put-away speed

- picking routes and walking distance

- replenishment efficiency

- congestion points

- supervision and safety

- scalability and future growth

Even small layout changes can significantly affect daily performance.

Common Layout–Flow Mismatches

Misalignment between layout and flow often causes problems such as:

- long and crossed picking routes

- mixing inbound and outbound traffic

- blocked replenishment paths

- inefficient use of space

- increased handling time

These issues are often mistaken for labor or productivity problems.

Best Practices for Aligning Layout and Flow

To ensure alignment between layout and operations:

- define operational flow before finalizing layout

- separate inbound, picking, and outbound zones

- apply ABC zoning to reduce travel distance

- place fast movers close to dispatch

- ensure clear replenishment paths

- use structured location coding

- validate flow during peak operations

Good alignment improves efficiency without increasing costs.

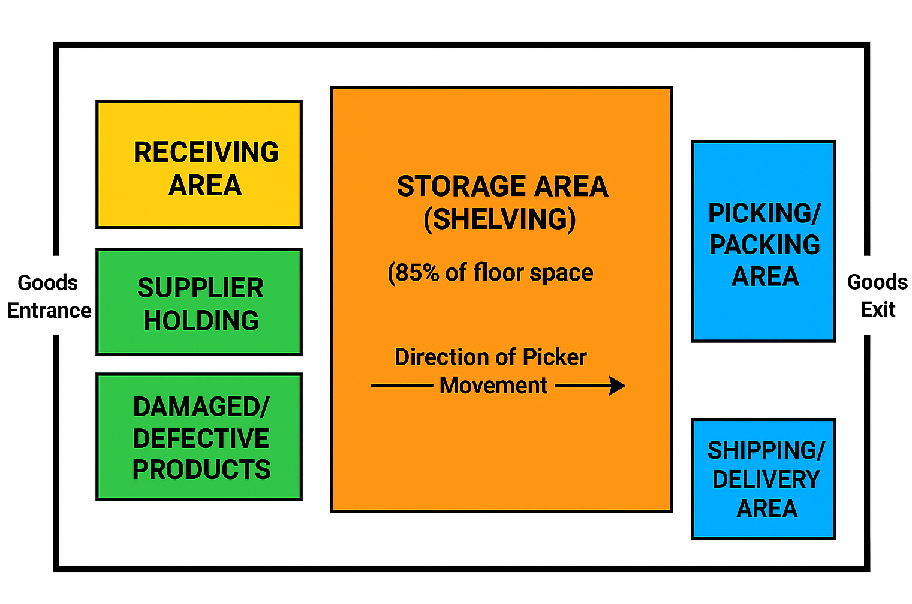

Below is a simplified warehouse layout that represents the functional zones and the direction of picker movement:

Layout :

- Receiving Area: Entry point for goods from suppliers.

- Supplier Holding & Damaged Products: Temporary storage for

quality check or defective goods. - Storage Area (Shelving): Occupies 85% of the space;

products are stored on shelves or pallets. - Picking/Packing Area: Orders are picked based on customer

requests and packed for shipment. - Shipping Area: Final dispatch zone; goods exit the warehouse here.

FAQ – Warehouse Layout and Operational Flow

Should layout be designed before defining processes?

No. Processes and flow should define layout decisions.

Can a good layout compensate for poor processes?

No. Layout and processes must be aligned to work efficiently.

Is one flow type better than others?

No. The best flow depends on volume, product mix, and space.

Can layout changes improve picking performance?

Yes. Proper zoning and flow design significantly reduce walking distance.

Do small warehouses need formal flow design?

Yes. Even small warehouses benefit from structured flow logic.