1. Why Budget Planning Matters in Warehouses

Effective warehouse budgeting allows managers to understand how resources are used, where costs originate, and how

operations can be optimized for better profitability. Small and medium-sized warehouses often work with tight margins,

so even small improvements in planning, labor allocation, or equipment usage can significantly reduce overall costs.

Warehouse teams frequently ask how much budget a warehouse should have or which cost categories matter the most.

The reality is that every warehouse is different, but the logic behind cost control is universal: visibility, structure, and consistent tracking.

The goal of this page is to provide a simple and practical framework for understanding warehouse costs and planning

a yearly or monthly budget.

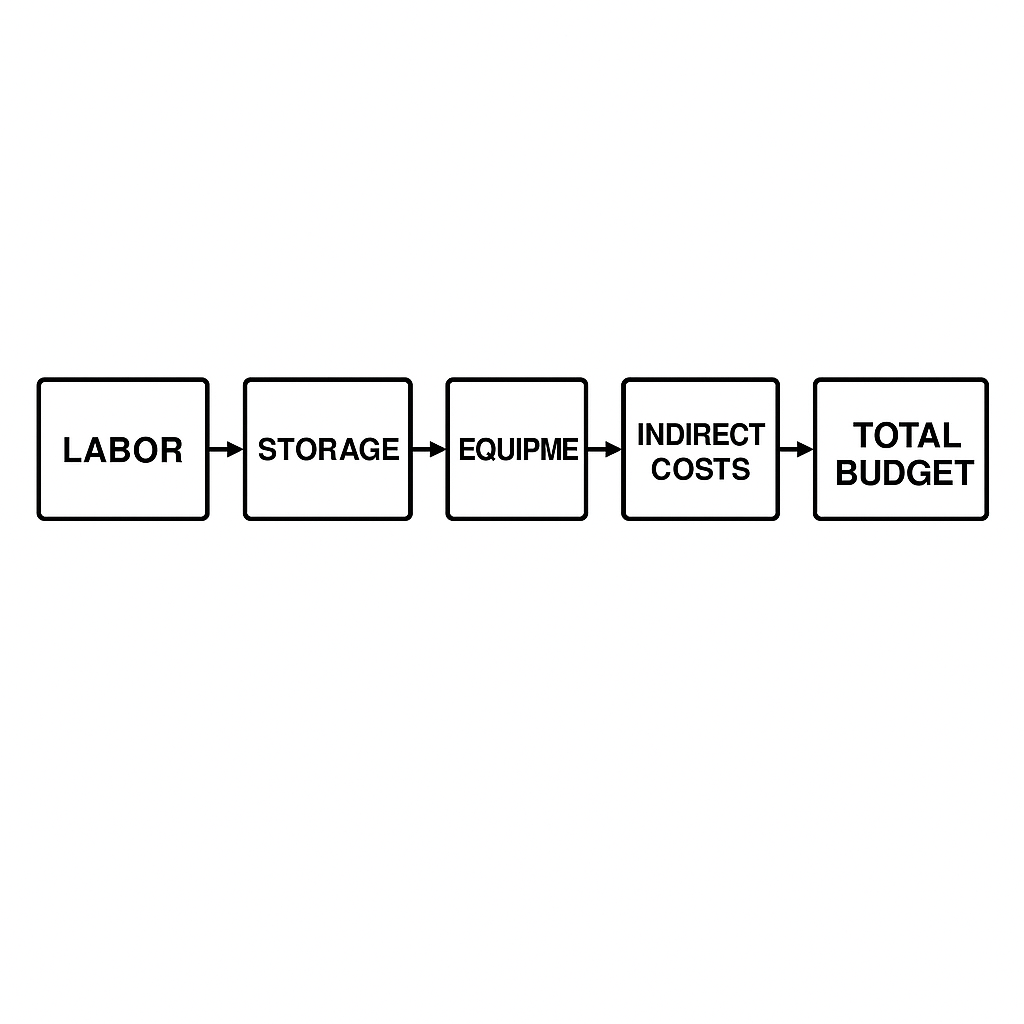

2. Main Cost Categories in a Warehouse

2.1 Labor Costs (the largest category)

- receiving

- putaway

- picking

- packing

- dispatch

- supervisors / coordinators

Labor typically represents 50–70% of warehouse operating costs, especially in manual operations.

2.2 Storage and Space Costs

- warehouse rent or depreciation

- utilities (electricity, heating, lighting)

- facility maintenance

- cleaning services

Space optimization can reduce these costs immediately.

2.3 Equipment and Asset Costs

- forklifts and pallet trucks

- batteries or fuel

- racking equipment

- repair and maintenance

- safety equipment

Well-maintained equipment directly reduces downtime.

2.4 IT and Systems Costs

- WMS or ERP (if applicable)

- scanners and printers

- labels and consumables

- small digital tools

Even without a WMS, digital tools improve accuracy and reduce errors.

2.5 Indirect Costs

- office supplies

- packaging materials

- protective equipment

- insurance

- security

These seem small but accumulate quickly.

| Budget Line | Description | Typical Components |

|---|---|---|

| Rent / Depreciation | Monthly cost for using warehouse space (rented or owned). | Rent, depreciation, insurance. |

| Utilities | Operational services required to run the warehouse. | Electricity, water, heating, waste management. |

| Maintenance & Repairs | Regular upkeep of the building and infrastructure. | Building maintenance, cleaning, safety checks. |

| Labor | Cost of the workforce involved in warehouse operations. | Salaries, overtime, temporary labor, PPE. |

| Equipment | Depreciation and operation of warehouse machinery. | Forklifts, conveyors, racks, pallets. |

| Other Costs | Non-recurring or exceptional expenses. | Damaged or expired stock, insurance claims. |

3. How to Build a Simple Warehouse Budget

- Identify all cost categories

- Estimate monthly averages

- Add seasonal variations if applicable

- Include safety stock for unexpected expenses

- Track deviations monthly

- Adjust labor or storage strategy as needed

Budgeting is simpler than most teams expect — the key is to update it consistently.

4. FAQ

Which cost category should I analyze first?

Labor — it has the biggest impact.

How do I reduce storage costs?

By optimizing layout, increasing pallet density, and improving slotting.

Is it necessary to track warehouse costs every month?

Yes — monthly updates help detect patterns and avoid surprises.

Does a WMS help reduce costs?

Indirectly: by improving accuracy, productivity, and stock visibility.

5. How to Use the Budget Calculator Below

The simple table below allows you to enter key cost elements and automatically calculate a total.

It is designed for quick estimates, planning exercises, and educational purposes — ideal for SMEs that need clarity

before building a full financial model.

Tip: The generated PDF report can be attached to monthly operational meetings, audit files, or financial forecasts.

Warehouse Budget – Simple Editable Table

Type monthly amounts in the last column. Empty cells are ignored. Use Print to PDF to export.

| Budget line | Notes (optional) | Monthly amount |

|---|---|---|

| Total | €0 |