1. What Is ABC Zoning and Why It Matters

ABC Zoning is a practical method for organizing warehouse space based on product movement and operational importance.

While ABC Analysis classifies items according to their value or consumption, ABC Zoning applies those results directly to the

physical layout of the warehouse.

In most small and medium warehouses, over 60–70% of daily picks come from only 10–20% of the products.

Placing these high-frequency items in the most accessible locations significantly reduces walking time, improves

picking accuracy, and increases overall productivity. Many warehouse teams ask where fast-moving products should be placed

or how ABC classification should influence layout design. ABC Zoning provides a simple, structured answer to these questions.

A well-designed zoning system helps operators move efficiently, reduces bottlenecks, and supports consistent

replenishment routines. It is one of the easiest improvement projects for SMEs because it requires planning, not expensive technology.

2. The Logic Behind ABC Zoning

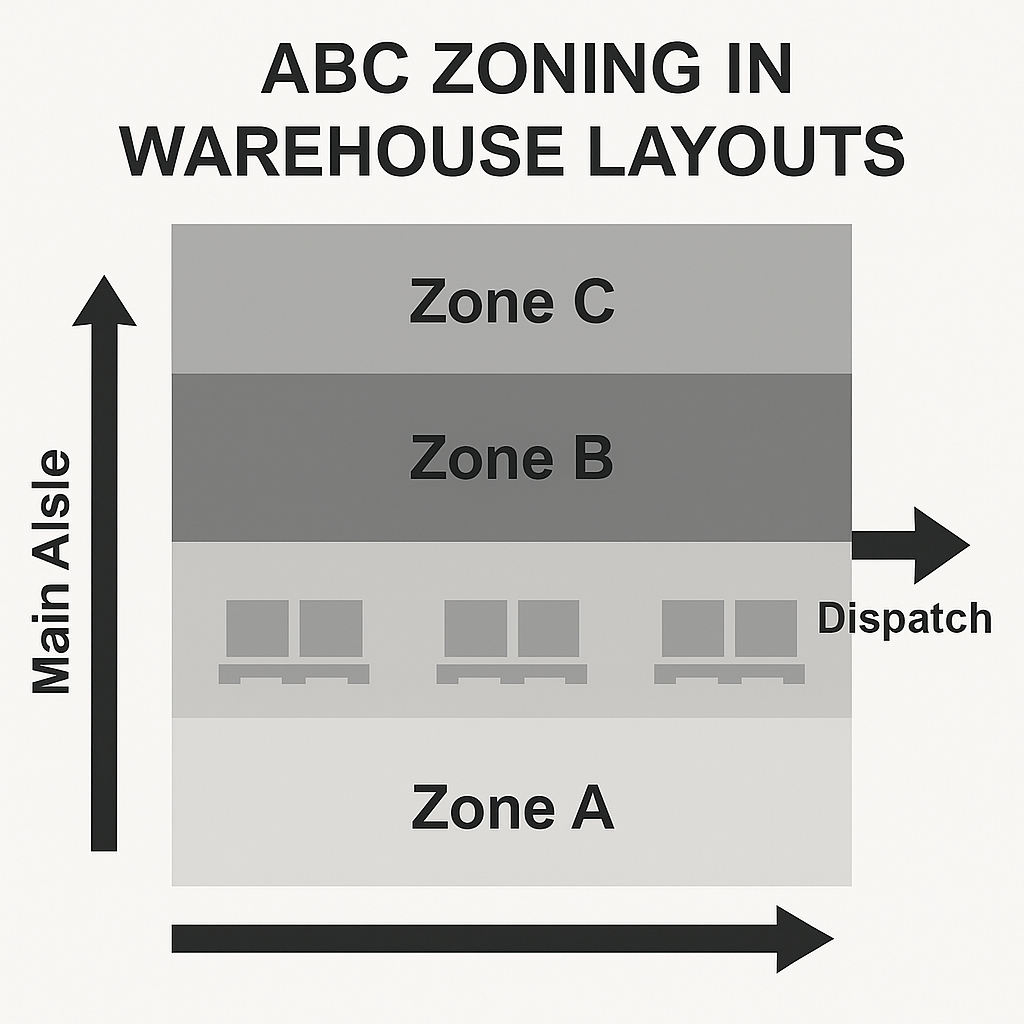

ABC Zoning distributes products into three physical zones:

- Zone A – for high-frequency items (A-items from ABC Analysis)

- Zone B – for medium-frequency items

- Zone C – for slow-moving or reserve items

Why it works:

- pickers walk less for high-frequency items

- replenishment becomes predictable

- workers learn layout faster

- minimal investment needed

- supports future digitalisation or WMS projects

ABC Zoning is not only about grouping products. It is about placing them where they generate maximum operational value.

3. Designing an Effective ABC Zone Layout

3.1 Define Picking Priority

Start by ranking products based on annual picks or order lines.

The top 10–20% become your A-items and will drive the layout.

3.2 Assign Warehouse Areas

The warehouse is divided into physical areas:

- near the dispatch/packing zone

- closest to the main aisle

- lower levels and easily reachable areas

- dedicated fast-pick areas

- vertical or back-of-warehouse areas for slow movers

Each area becomes a zone:

- Zone A → closest + lowest levels

- Zone B → medium distance

- Zone C → upper levels or distant areas

3.3 Use ABC to drive both layout and replenishment

The purpose is not only to place items correctly but also to:

- reduce travel distance

- simplify replenishment paths

- eliminate congestion

- support batch or wave picking

- improve ergonomics

4. Examples of ABC Zoning (SME-Friendly)

Example 1 — Simple layout with 3 aisles

- Aisle 1, Level 1 = Zone A

- Aisle 1, Levels 2–3 = Zone B

- Aisle 2–3 upper levels = Zone C

Example 2 — Larger warehouse

- Zones are grouped by picking distance:

A (0–15 meters), B (15–40 meters), C (40+ meters) - A-items placed closest to dispatch

- C-items placed in remote or high locations

Example 3 — Mixed pallet & case picking

- Zone A = ground level case-pick

- Zone B = mixed case & reserve

- Zone C = pallet reserve in racking

5. Some Q&A

Warehouse managers often ask how frequently zones should be updated.

The best practice is to revisit zoning every 3–6 months, or after major assortment changes, to ensure

that A-items remain in the optimal area.

Another common question is whether ABC Zoning requires a WMS.

The answer: No.

ABC Zoning is fundamentally a manual layout improvement. It works perfectly with basic tools,

labels, and disciplined processes.

A WMS only helps maintain zoning consistency over time.

Operators also ask whether zones must be perfectly symmetrical.

Not necessarily. Warehouses rarely have ideal geometries. The goal is operational efficiency, not perfect symmetry.

6. How ABC Zoning Improves Picking Efficiency

By placing A-items close to the main aisle or dispatch area, walking distance can be reduced by up to 30–40%.

Key benefits:

- fewer steps per pick

- fewer picking errors

- easier training for new staff

- better route optimization

- smoother replenishment processes

Zone A also becomes a natural candidate for implementing advanced picking methods such as:

- wave picking

- batch picking

- zone picking

- pick-and-pass systems

7. Best Practices When Implementing ABC Zoning

✔ Keep zones clearly labeled

Use color codes or large signs.

✔ Ensure labels match location coding

Zoning must align with your aisle–bay–level structure.

✔ Keep A-items at ergonomic heights

Operators pick faster when items are between hip and shoulder height.

✔ Avoid mixing A, B, and C items within the same small area

Clarity reduces mistakes.

✔ Review zone boundaries regularly

Assortments change, and zoning must adapt.

✔ Combine zoning with replenishment logic

A-items require more frequent replenishments; plan routes accordingly.

8. How ABC Zoning Supports Digitalisation

A warehouse prepared with ABC Zoning is easier to digitalise because:

- WMS location mapping becomes cleaner

- slotting logic is predefined

- replenishment rules are clearer

- scanning flows are simpler

- users already understand product movement patterns

This preparation reduces implementation time and WMS configuration errors.