1. Why the Stock Controller Role Matters

A Stock Controller is one of the most important operational roles in any warehouse.

This position ensures that every item stored, moved, or shipped is accurately recorded.

High stock accuracy leads to reliable picking, smoother replenishment, faster customer service,

and fewer financial discrepancies. In small and medium-sized warehouses, the Stock Controller

is often the key person connecting receiving, storage, picking, counting, and reporting into a single consistent flow.

Warehouse managers frequently ask how a stock controller helps improve daily operations or whether the role

is needed when the warehouse is small. The truth is that inventory accuracy does not depend on warehouse

size — it depends on discipline, well-defined routines, and one person who ensures that all stock movements

are recorded correctly. A stock controller brings exactly this structure.

2. Main Responsibilities of a Stock Controller

2.1 Ensuring Stock Accuracy

- Matching physical counts with system records

- Investigating discrepancies

- Validating adjustments with supervisors

2.2 Monitoring Inventory Movements

- Controlling receiving and putaway accuracy

- Verifying picking and dispatch correctness

- Checking returns and damaged goods handling

2.3 Maintaining Location Integrity

- Ensuring products are stored in correct locations

- Supporting re-slotting when layout changes

- Updating location changes in the system

2.4 Running Regular Stock Checks

- Cycle counts

- Spot checks

- Full inventory counts when needed

2.5 Supporting Warehouse Processes

- Helping teams understand correct handling

- Training new employees on stock routines

- Reporting slow movers, missing items, or misplacements

A Stock Controller does not just “count items” — they maintain the operational truth of the warehouse.

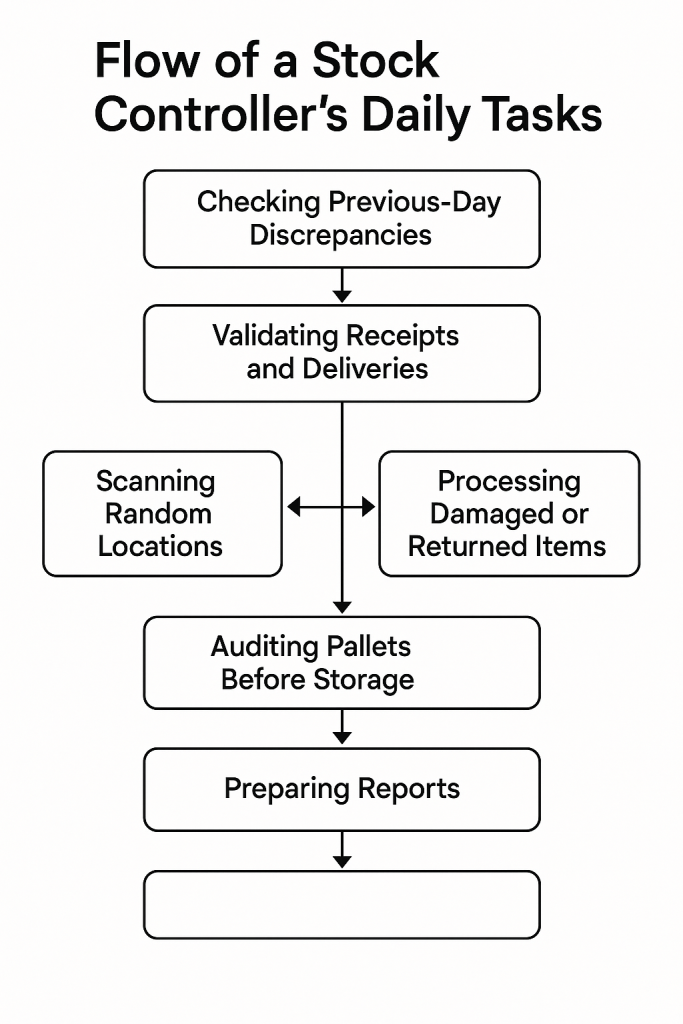

3. Daily Tasks of a Stock Controller

A typical day includes:

- checking previous-day discrepancies

- validating receipts and deliveries

- scanning random locations for accuracy

- ensuring damaged or returned items are correctly processed

- auditing pallets before storage

- preparing reports for supervisors

Even small inconsistencies found early prevent major operational problems later.

4. Natural FAQ

Is a stock controller necessary if the warehouse uses a WMS?

Yes — the system only reflects what operators record. Without a responsible person validating processes, errors accumulate.

How many stock controllers does an SME need?

Usually one full-time controller for every 8–12 warehouse operators.

Should the stock controller be independent from picking?

Ideally yes — independence ensures unbiased checks and more accurate results.

5. Skills Required for a Strong Stock Controller

Technical Skills

- good understanding of warehouse processes

- basic WMS or ERP skills

- barcode scanning accuracy

- ability to analyze discrepancies

Soft Skills

- attention to detail

- discipline and consistency

- communication with operators

- ability to train and guide colleagues

- problem-solving mindset

In SMEs, the Stock Controller is often a hybrid role that supports both operations and data accuracy.

6. Importance of the Stock Controller for SMEs

High stock accuracy leads to:

- fewer picking errors

- less time wasted searching for missing items

- faster replenishment

- better supplier accountability

- improved financial reporting

A reliable Stock Controller is one of the best operational investments for a growing warehouse.

7. Recommended Internal Links

- Inventory Management

- Importance of Location Coding in Warehousing

- 5S in Warehouse Management

- ABC Zoning in Warehouse Layouts

- Assign Products to Storage Locations

Related Resources :

- Ad-Hoc Inventory Improve Stock Accuracy – Explore how a Stock Controller initiates fast and effective

inventory checks (article in Blog).