Why Sales and Logistics Misalignment Happens

Sales teams focus on revenue, speed, and customer promises. Logistics teams focus on capacity, accuracy,

and operational constraints. When these perspectives are not aligned, decisions are made in isolation, leading to

unrealistic commitments, inefficient flows, and increased operational pressure inside the warehouse.

Impact on Warehouse Operations

When sales and logistics do not share the same data language, the warehouse is directly affected:

- unstable order volumes

- last-minute priorities

- congestion in picking and dispatch

- frequent stock exceptions

- increased returns and adjustments

Most operational issues originate upstream, not on the warehouse floor.

How Shared Data Improves Collaboration

Shared master data and common performance indicators help align decisions:

- product data defines realistic lead times

- location and capacity data support sales promises

- stock visibility reduces emergency orders

- standardized processes improve predictability

When sales and logistics rely on the same data structure, collaboration becomes operational, not theoretical.

The Hidden Cost of Disconnected Decisions

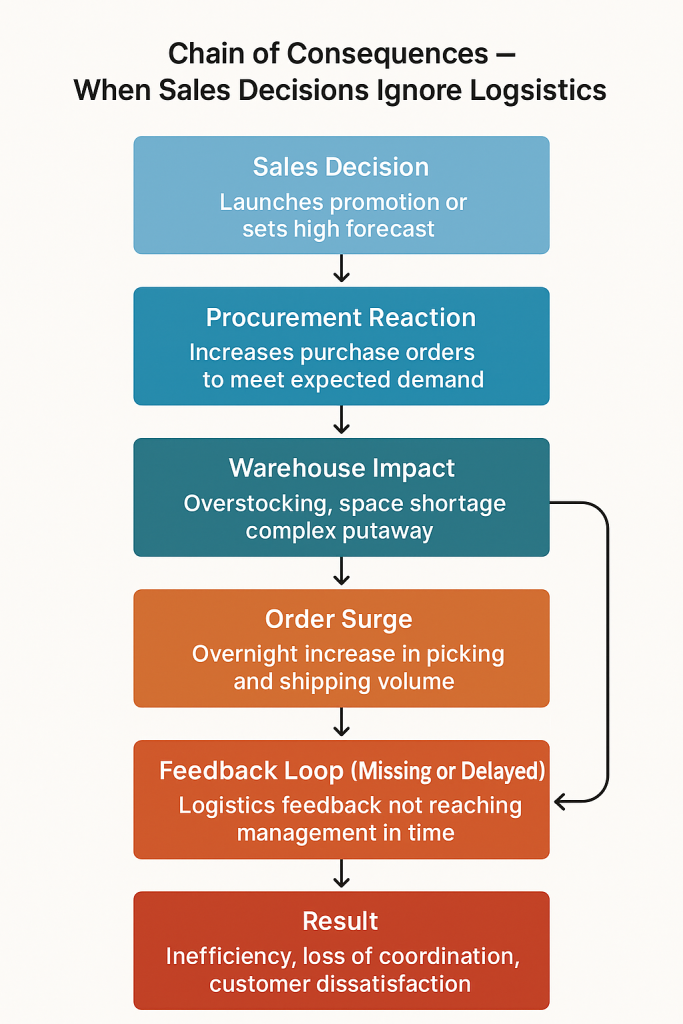

When management or sales teams plan promotions, forecast sales, or launch new products without involving

logistics, they often trigger a silent chain reaction.

Overstocking, bottlenecks, and last-minute delivery pressure are not just operational issues — they are symptoms

of poor coordination between departments.

A decision made in isolation may look brilliant on paper but disastrous in execution. Logistics is the first

to feel it — and often the last to be consulted.

The Typical Scenario

Let’s look at how this happens in real life:

- Sales announces a promotion → warehouse receives double the inbound volume.

- Procurement reacts to optimistic forecasts → stock levels explode beyond capacity.

- Sudden order surges overnight → warehouse must add shifts or overtime to keep up.

The result: high costs, lower accuracy, frustrated teams, and sometimes delayed deliveries.

The problem isn’t effort — it’s disconnection.

Why It Happens

The root cause is a fragmented decision process:

- Sales targets are set independently from logistics capacity.

- Procurement follows sales optimism rather than stock visibility.

- Management expects agility without providing real-time coordination tools.

- Feedback between departments is limited or purely reactive.

Without a shared information loop, every decision becomes a local optimization that harms the system as a whole.

The Systemic View

In logistics, everything is connected.

Promotions, purchasing, storage, and delivery are not isolated actions — they are interdependent parts of a single flow.

When sales and logistics work separately, inputs grow unpredictably, processes lose stability,

and outputs (deliveries, services) suffer.

The logistics system thrives only when the flow of information accompanies the flow of materials.

Building Alignment

To restore balance, decisions must become systemic again.

That means including logistics not only in execution but in planning.

Practical steps include:

- Collaborative forecasting: align sales campaigns with warehouse capacity and transport resources.

- Shared dashboards: give logistics real-time visibility into upcoming promotions and expected volumes.

- Impact analysis: evaluate every sales initiative not only by its revenue potential but also

by its logistics cost and operational load. - Continuous feedback: plan → execute → measure → adjust — and repeat the cycle.

When each department learns from the same data, coordination becomes natural.

FAQ – Sales and Logistics Alignment

Why do sales and logistics often conflict?

Because they use different metrics and operate with different priorities.

Is this a warehouse problem?

No. It is a cross-functional alignment problem that impacts warehouse operations.

How can small companies improve alignment?

By using shared master data, simple metrics, and clear operational rules.